Operation principle

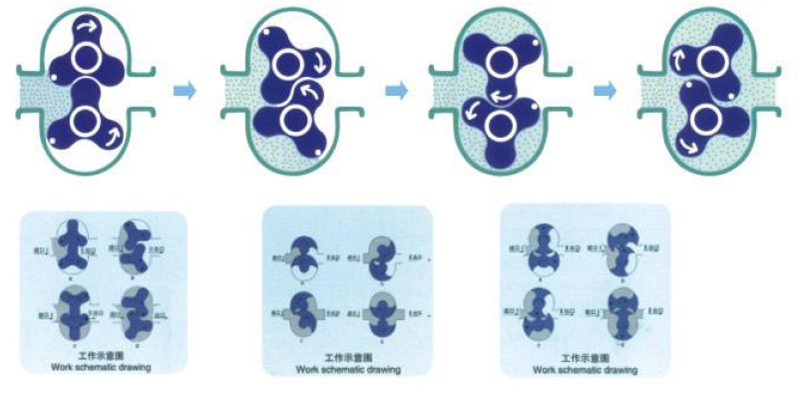

Santiary Rotor Lobe pump is also named rotary lobe pump, positive displacement pump,three-lobe pump, sole pump, etc. As the lobes rotate,the chamber between lobes and the outer casing are successively filled with Viscosy product,which is transfered to discharge nozzle with a fixed amount of displacement.The pumped medium forms a continuous stream thanks to the tolerances between the lobes and the pump casing, thus ensuring an efficient pumping.When the 2 simultaneous reverse rotating ro tors (with 2-4 gears) revolve, it produces suction force at the inlet (vacuum), which intakes the material delivered. The 2 rotors divide the rotor housing into many smaller parts and revolve in the sequence of a—b—c—d. When it revolves to position a, only housing I is filled with medium; when it revolves to position b, housing B encloses part of the medium, when it goes m position c, housing A encloses medium, and finally it goes to position d, then housing A, B and II are interlinked and the medium is transported to the outlet. As this process is repeated, medium (material) transported continuously.

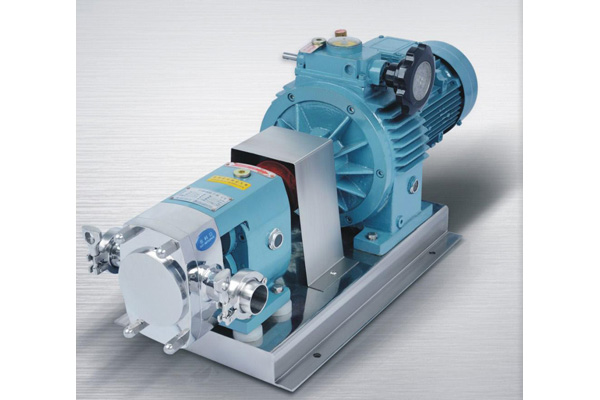

Transmission of rotor pump:the rotor pump generally has the following transmission forms

1. Motor + fix velocity ratio speed reducer: this form is simple that the rotor speed is constant. So the flow is not adjustable. If frequency transformer is all ccated, the speed adjustment can be achieved.

2. Motor + mechanial friction type stepless speed variator: the speed variation of this speed variator is realized through manual adjustment. It is characterized by safe and reliable operation, as well as stepless adjustable flow. The flaw is that it is non-automatic adjustment,which is difficult. The speed adjustment can be available only when it works.

3. Frequency conversion motor + frequency converter: automatic adjustment of rotaticn speed can be realized in this way, and also stepless adjustment of flow can be realized. The advantage is a higher degree of automation and easy to operate. The drawback is the higher price and smaller low-speed torque.

Application range of rotor pump

1. Food and beverages: dairy products, latex,chocolate, syrup, cheese, wort, beer, soda water, cream, concentrated fruit juice, wort and fermented liquid.

2. Fruit concentrates: pudding, jam, jelly and ketchup.

3. Paste products: fat and grease etc.

4 Cosmetics: face cream, detergent,hair style gel and essence oil etc.

5. Medicine: extract emulsion and pill liquid etc.

6. Chemical industry: dye, fat, solvent, resin and polymer etc.

7. Others: candy industry, baking industry and chemical industry etc.

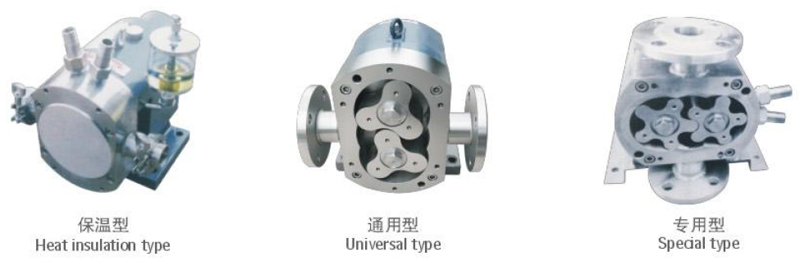

Pump Head Structure

Rotor Pump Exploded View

Rotor Pump Work Simulation Diagram

Rotor Vane Quantity Selection Reference

Single impeller

Used to transfer medium with a little large grains,its unique shape and curve type make it have advantage in the transportation oflarge particle materials and can avoid the large particles damage effectively.

Double impeller

Used to transfer materials or fillings with particles and it is with low damagerate. This pump is suitable for transferring materials with poor liquidity or containing Particles.

Tri-impeller

This is commonly type,the capacity and performance is better than the single and double impeller

Multi-impeller

When impeller quantity beyond three,the capacity will decrease when impeller increase Multi-impeller has high stability whileusing,but easy to damage grain medium.

Butterfly rotor pump

As it adopts the butterfly rotor,in addition to having the features of common rotor pumps,it also has certain advantages when conveying materials of high viscosity and those containing large granules,and is suitable for effective conveying of very viscous materials.

single butterfly curve rotor pump(granule rotor pump):

This pump is specially designed and manufactured for conveying materials that contain large granules.It's unique shape and curve form enable it to have incomparable advantages over other pumps when conveying materials that contain large granules,During the conveying of materials,it is able to effectively prevent the granules from being broken.It is a preferred pump for conveying materials that contain granules.

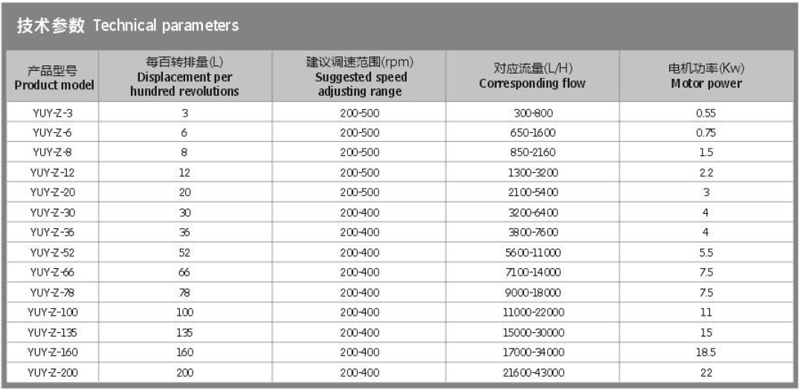

Note:The flow range in the table refers to the data measured when medium is water.

The pump adopts stepless speed variator or frequency converter for speed adjustment within the range of 200~900rpm

When the pump conveys strong liquids of high viscosity,the motor power should be increased

For media with relatively poor flowability,it is suggested that the pump with matching flow should be used for conveying at the inlet

You will not be notified of any modifications to the data in the table.The parameters of the real products shall prevail.

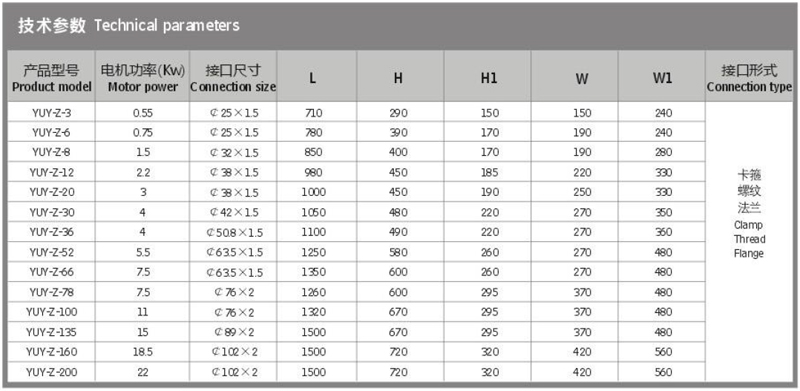

Outline dimensions

- 2018-01-15

- 2018-01-15