Food grade stainless steel centrifugal pumps are used in the food-processing and pharmaceutical, dairy, milk industries.Some of its uses include processes in the brewing, dairy and beverage industries, and with the appropriate options it can also be used in complex applications such as:Evaporators, concentrators, distillation towers, decanting of syrups, and purified-water loops in the pharmaceutical industry.

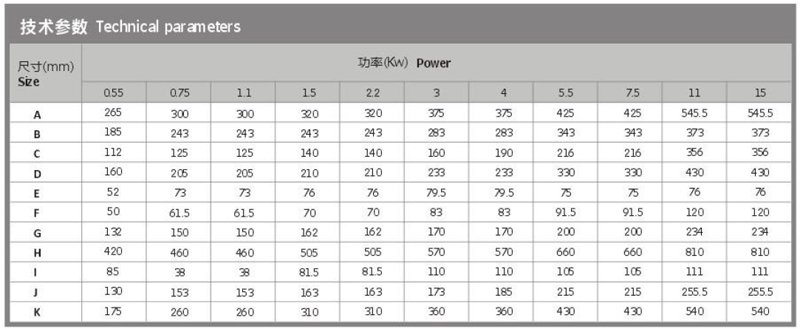

Technical parameter:

| Specification | 1T-500T, 055KW-75KW |

| Materials |

SUS304 SUS316L (In the selection of materials, all parts that contact the materials such as pump body, pump cover and Impeller are made of SUS316L or SUS304 stainless steel.) |

| Standards | DIN, SMS |

| Impeller | Open impeller, without dead corner of sanitation |

| Work Condition |

The sanitary centrifugal pump adopts horizontal conveying with high and low liquid levels. It is not of self-priming type. (Please select the self-priming pump for self-priming type.) |

| Surface Treatment |

The liquid receiving part is subject to polishing treatment and other parts matte or sandblasting treatment. |

| Maximum inlet pressure | 0.5MPa |

| Temperature range | -10°C to + 140°C(EPDM) |

| Washable mechanical seal |

Water pressure: Max. 0.1MPa Water volume: 0.25-0.5L/min |

Motor:

1、Depending on the configuration, the pump mainly adopts "ABB'' brand high-efficiency M2BAX three-phase AC motor. The pump is designed and manufactured according to IEC60034.IE60072,conforming to CE marking requirements.

2、The explosion-proof motor is available to meet the needs in different applications.

3、With excellent electric performance, low noise and low vibration, the motor is designed to have standard protection grade of IP55 and insulation grade of grade F.

4、Frequency: 50Hz/60Hz

5、Woking mode: continuous (SI)

6、Rotation speed: The standard rotation speed of the pump is 2900r/min.

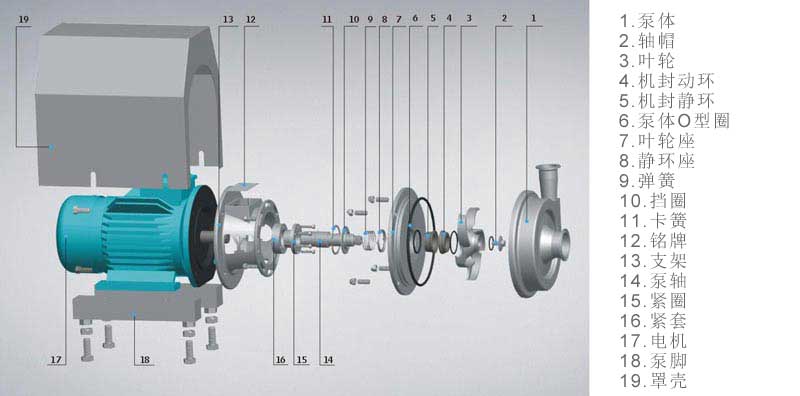

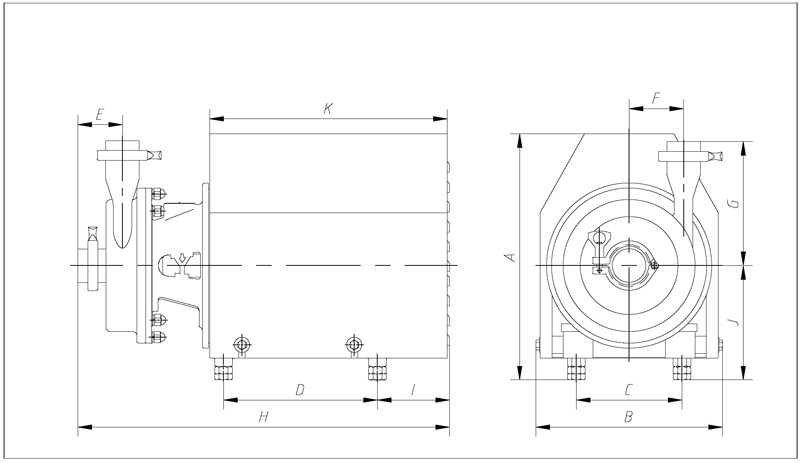

Structure exploded figure of YUY-L series sanitary centrifugal pump

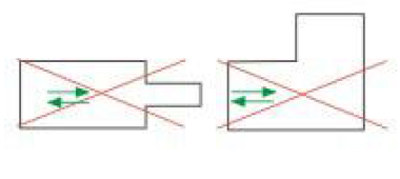

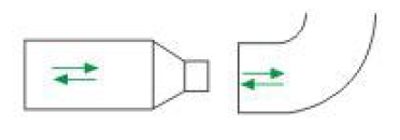

Connection ways of pump inlet and outlet

Energy loss of liquids may occur in the pipe. The loss falIs into friction loss and local resistance loss. The smoother the pipe is, the lower the friction loss is. The fewer the bend is, the lower the pipe diameter change is, and the lower the local resistance loss is. Therefore, try not to use rough pipes for connection, and avoid using the method of rapid pipe changes during the connection.

Wrong pipe type

Right pipe type

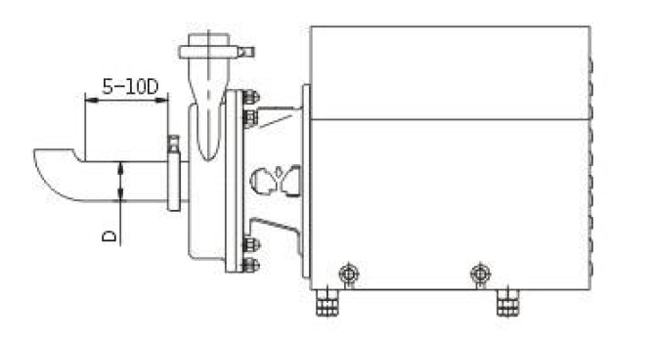

Pipe diameter and connection distance

When the pump runs under small flow, the efficiency is very low, and the energy consumed makes the liquid temperature rise rapidly. When the pump runs under small flow, the return flow that passes the impeller interval will increase, causing increased damage of pump pressure pulse, vibration, noise, etc. Therefore, it is better that the connected pipe inlet diameter should be more than or equal to the designed inlet diameter. In order to ensure that the pump runs more stably, it is necessary to connect with a long straight pipe at the pump inlet, with its length 5-10 times longer than the pipe diameter.

Pipe connection distance

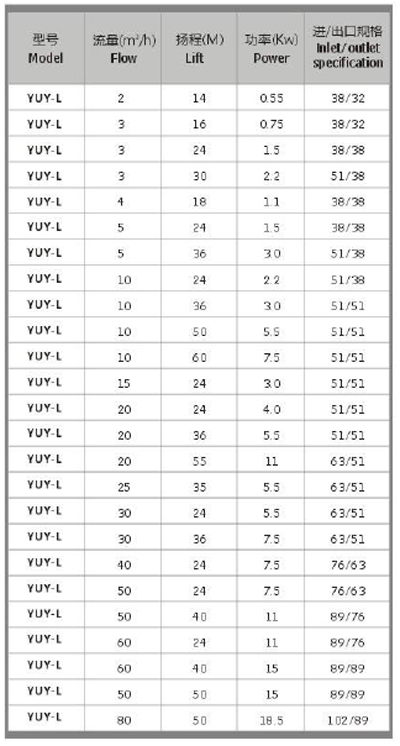

YUY-L series performance and model selection table

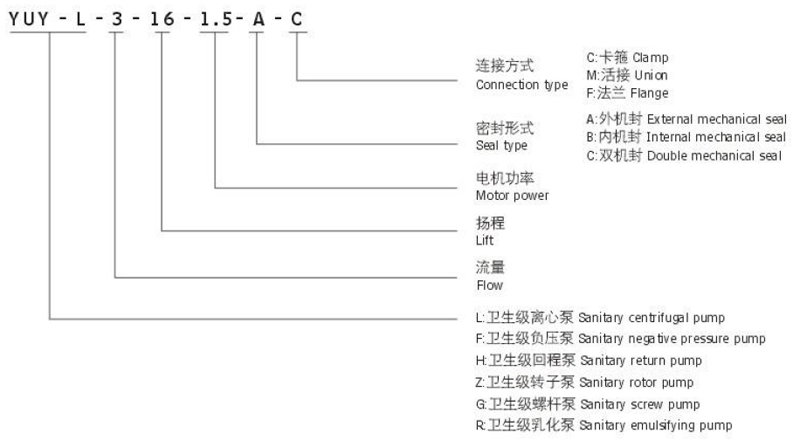

Model descriptions of YUY sanitary centrifugal pump

For Example

- 2018-01-15

- 2018-01-15